Easily Single or Multiple Grooves for Your Successful Solution

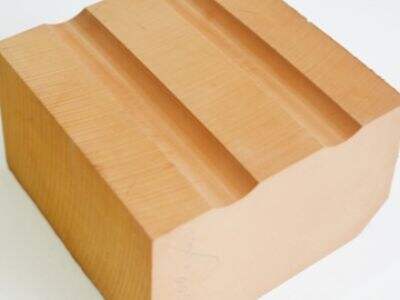

Depending on whether there's a singular groove or multiple ones, it can be either a groove system or a single groove. The most basic Friction Liner type is a one-groove system, usually for small jobs or projects. These one-groove systems are simple and uncomplicated making them ideal for small-scale applications. Particularly devices with more than one ridge are elaborate and are made use of for larger jobs that ask for more grip and aid with smooth, hefty or awkward loads.

Same goes with the speed and efficiency of the groove system, which can be altered by the amount of grooves that the system has Imported Liner. Typically, a higher-groove number system provides increased grip and is more suitable to heavy-duty work. This is handy, especially in cases where things need to be transported fast without destination. Though more grooves mean more money too, that's reality best not forgotten. Which shows its importance to select the correct system based on your requirement of your job.

Why Groove Systems Are So Versatile

Tip: Groove systems are used for a wide range of applications and they can be used in a wide range of industries. Groove system Liner Block for Head Sheave and Guide Wheels are often used in conveyor systems. Conveyor systems are valuable machines that aid the transportation of materials from one point to another to facilitate smoother and quicker working. Such systems are frequently seen at factories that require perpetual transportation of products. Apart from that, groove systems can also be used in other industries as well; such as manufacturing, farm and food.

The ability to provide customizations is one of the best attributes of groove systems. That can be cut, fitted, and programmed to suit various job requirements. The grooves, for example, can be formed in such a way that materials of different shapes and sizes are accommodated. Such versatility allows groove systems to used in many types of industries from food processing plants to automotive manufacturers.