Hunting for a dependable supplier and safe friction liner? Take a look at top-rated provider Weka Mining Machinery. They feature exceptional quality items with innovative designs to generally talk with your entire mining needs.

Advantages:

Our friction liners are actually produced utilizing the quality greatest products, guaranteeing security as well as resilience. Each liner was actually created cutting-utilizing side withstand damages as well as maintain its own security throughout treatment. Additionally, our provider offers inexpensive prices compromising on quality, creating all of them your perfect option for friction liner requirements.

Innovation:

Innovation is key to our method of satisfying customer. They truly are always researching to improve their items, and also this can be clear within their friction liners. The liners are made with features such as for example low friction coefficients and high-temperature resistance as well as others, which promote efficient hoist operating and a lengthier lifespan.

Security:

Safety is a must in almost every mining procedure, and our supplier understands this. Their friction liners were comprised of safety in your mind, ensuring they steer clear of the hoist from slipping or jamming during use. The liners also provide robust anti-corrosion and characteristics which are anti-wear that assist lower the opportunity for accidents to your working environment.

Use:

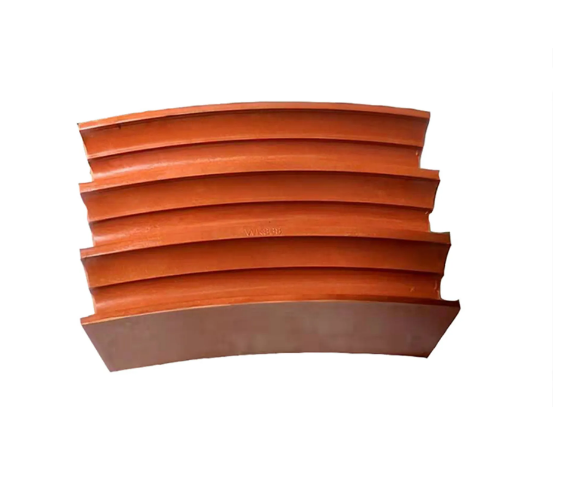

Our friction liners are suited to usage in several types of mine hoists and elevators, including underground and surface hoists. Also versatile, providing an easy wide range of different cable types and hoist conditions. Our provider offers numerous types of liners, including conical, cylindrical, and flat-shaped, enabling one to get the fit perfect for the particular requirements.

Simple Tips to work with:

The friction liners are not too hard to set up. First, ensure that the hoist unit is immobilized and then the engine is turned down. Then, eliminate the old liner and clean the surface where the new liner shall be installed. Next, place the liner inside the appropriate career care never to over-tighten the bolts. Finally, switch on the motor and test the hoist's functioning to make sure this new liner is made and works correctly.

Service:

Our consumer service is first rate. They give you timely and answering support effective customer inquiries and concerns. The supply process is also seamless and fast, with services and products being delivered straight to your doorstep. This, along making use of their quite product good warranty customer service.

Quality:

Our provider's friction liners are available using high-quality materials, including composite materials and stainless steel. Each item is faced with rigorous quality tests to make sure premium performance. Their quality standards make sure each liner can withstand the harsh mining, supplying hoist optimized performance.

Application:

Our friction liners have a wide variety of application in diverse industries such as for example mining, metallurgy, and transport. The liners' versatility means they are perfect for utilized in numerous kinds elevators and hoists, including large-scale mining, where efficient and safe hoist operation is important.