Have you ever seen a big old crane lifting something really heavy really high into the air? These incredible machines seem like they could work wonders, but they also have specific components that help them function safely and efficiently.

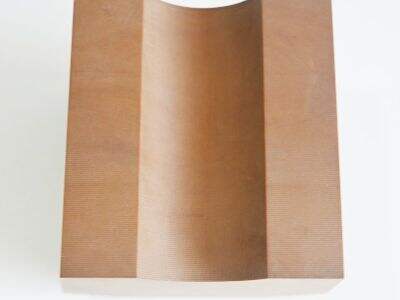

Liner block — it is a very critical small but a very significant part in a crane. A liner block may be small, but it does an oversized job. It slips through and into the pulley of a crane. A pulley is a round wheel with a rope around it used to pull or lift something up high. Liner blocks make sure the rope runs freely, like putting oil on your bicycle chains helps it rotate.

The plastic liner are made of a super tough type of plastic called polyurethane. It is next-generation tough plastic for use in very demanding environments such as construction sites, mines and factories. The blocks help the rope operate smoothly without bind or severe wear. Instead of wearing fancy shoes that dissipate the energy provided by your legs to help you walk longer and tireless, these blocks are to a crane like fancy shoes; they are the lifecycle secrets of cranes.

Cranes use these unique liner block to hoist all kinds of huge and heavy objects. They are so powerful they can lift huge metal beams as heavy as a truck, large machinery weighing more than a house, and even pieces of buildings. The liner blocks ensure that the crane features safely and it could lift heavy items without developing a fracture or obtain getting damaged.

Big machines have special doctors too, and the people who put cranes together are those doctors. They do spend time figuring out how to make these cranes work perfectly. They understand the importance of each micro component, even a frigging liner block. If the liners are in good shape on a crane, it can move things at a speed, without damaging the machine. The goal is to help workers do their work better and work safely.

It would be a little like trying to pull a very heavy wagon. If the wheels were rusty and jammed, it would be difficult to move, correct? Liner blocks are the magic wheels that allow cranes to move in a sliding motion. They lower a thing called friction, which is the thing that makes stuff difficult to move.

So the next time you see a giant crane picking up something heavy, take a closer look. And those little polyurethane products are at work helping the crane do its thing, which is pretty remarkable. They may be mini, but they play a major role in safely hoisting heavy loads in a timely manner for large machinery.

Liner blocks are the superpower of cranes.